Pegmatite mine, open-pit and small underground part.

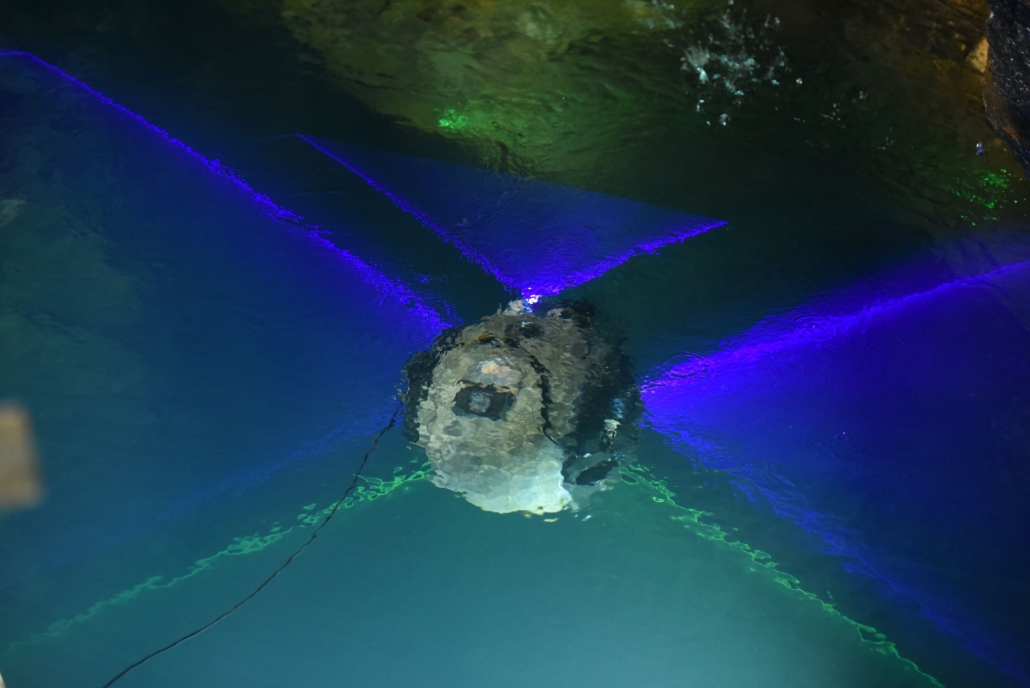

UX-1 was successfully tested in a real life environment

Two test sites: shallow part, and deep part of the quarry

Navigational and ballast systems were tested and worked well

Depth control system tested and proved to be working

2-hour long dives approximately

Maximum depth of about 30 meters

Successful mapping of old underground drive

MSU camera and LED synchronisation were successfully tested outside the water*

*not tested on any dive, one of the control board was broken by accident

Mercury mine, UNESCO World Heritage site.

Movement, control and 3D mapping to explore shafts in confined environments

Total of 11 dives within the span of two weeks

Fully autonomous dive of the robot to the depth of about two meters

UX-1 reached the bottom of the shaft at 26,2 m and mapped the entire area

- Approximately two hours, 1.5h for the descent to the bottom of the mine and approximately 0.5h for the return to the surface

The pendulum system was tested with dives at different pitches (0° and 90°)

The multispectral camera unit has been proven to be working well

The robot has proven to be working well in very challenging environments

Uranium mine in granite pegmatite.

Total of 18 dives

Maximum depth reached at 106,5 meters

Mine’s main shaft as well as side tunnels have been explored and mapped

Video footages, point clouds of the shaft and side tunnels

Multispectral images and UV fluorescence lights of the rock wall

Focus on debugging the software and improving hardware to eliminate problems and correct open issues

All key success factors were achieved, making this trial a successful one

Cu–Zn-Pb mine flooded in 1858 and never previously resurveyed.

Up to 125m depth. Total of 10 dives, in 3 shafts

Two robots to navigate and acquire data from the mine (UX-1a and UX-1b)

The data collected include video footage and point clouds

The control systems were successful in maintaining the desired depth during the dive

Data processing provided rapid access to high resolution videos from all five cameras, for LED ‘white’ illumination and for ultraviolet illumination

3D models constructed from sonar and SLS data showed the size and shape of mined pipe workings

During the Ecton test period the robots successfully collected data from MSU, EC and pH meter and subbottom profiler. UX-1b also collected water samples with Water Sampler Unit

Cave system reaches up to a length of 6km, with sections up to 100m depth

Selected location to test and improve the prototype’s autonomy

New testing environment for the project team and the UX-1 robots

10 autonomous navigation missions were successfully achieved